|

Customer: |

Permacel Division of Nitto Denko |

|

Location: |

Pleasant Prairie, WI |

Project Summary

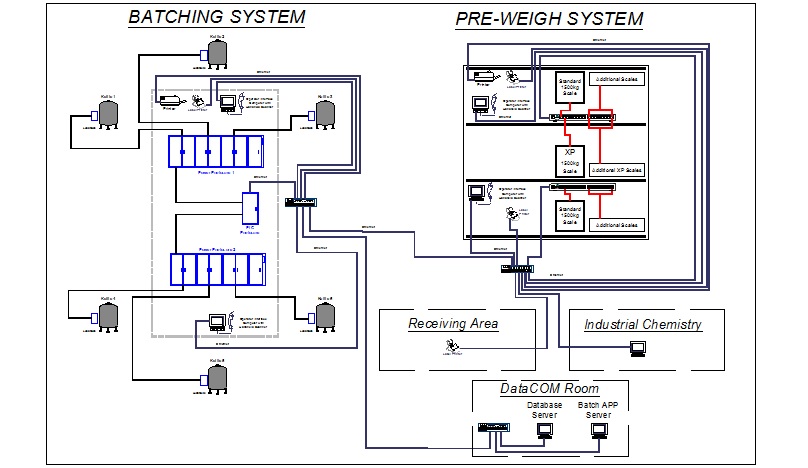

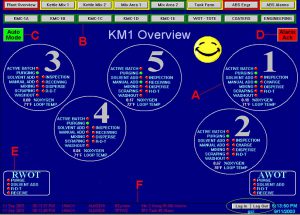

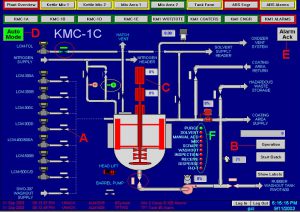

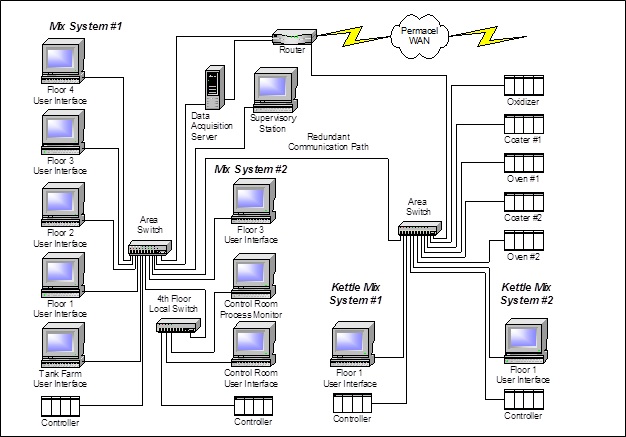

- Development of S88.1 compliant batch control system for adhesive film manufacturing site with four major process cells distributed through several mix buildings.

- (4) Rockwell ControlLogix processors with ControlNet to Intrinsically Safe ControlNet via fiber optic communication.

- 2000 I/O points provide control for total of 22 processing units with shared tank farm and utility resources.

- System uses Wonderware HMI front end on (11) workstations with custom phase control engine developed for ControlLogix sub-system.

- Provided intrinsically safe electrical design for all areas in facility, which are NFPA Class I, Division 1 and 2 rated.

- Designed and implemented information store and web based reporting system using Wonderware Historian and Information Server products.

System Architecture